A Tool for Every Problem

Okay, we may not have the tool for “every” problem, but with 40 plus years behind us, we have the background, experience and yes, probably the tool.

We Keep it Clean

Here at RTD we take pride in maintaining a clean shop floor. The first step to providing quality work is having a quality space to work in.

Don't believe us? Let's set up a time for you to come by and see the RTD difference for yourself.

Our Facilities

Doosan Lynx 2100LSYB

Our most recent addition. The Lynx is a Twin Spindle Live Tooling Turning Center. With the addition of an LNS QLS80 Servo Bar Feeder, Chip conveyor & Parts Accumulator, we have the ability to run lights-out 24 hours a day.

Fadal 6030 VMC

Our Largest VMC, The 6030 has a capacity of 60" x 30" and with a little creativity, we can usually machine parts that are even larger.

Mitsubishi FX10 Wire EDM

A small machine by today's standards, The FX10 has become an important part of our business. It’s a specialized machine that is primarily used for the machining of very accurate and/or intricate shapes into ferrous metals. Whether it's putting a simple keyway in a hub, or machining Titanium parts from a solid, having the capability in-house allows us to better schedule and maintain quality.

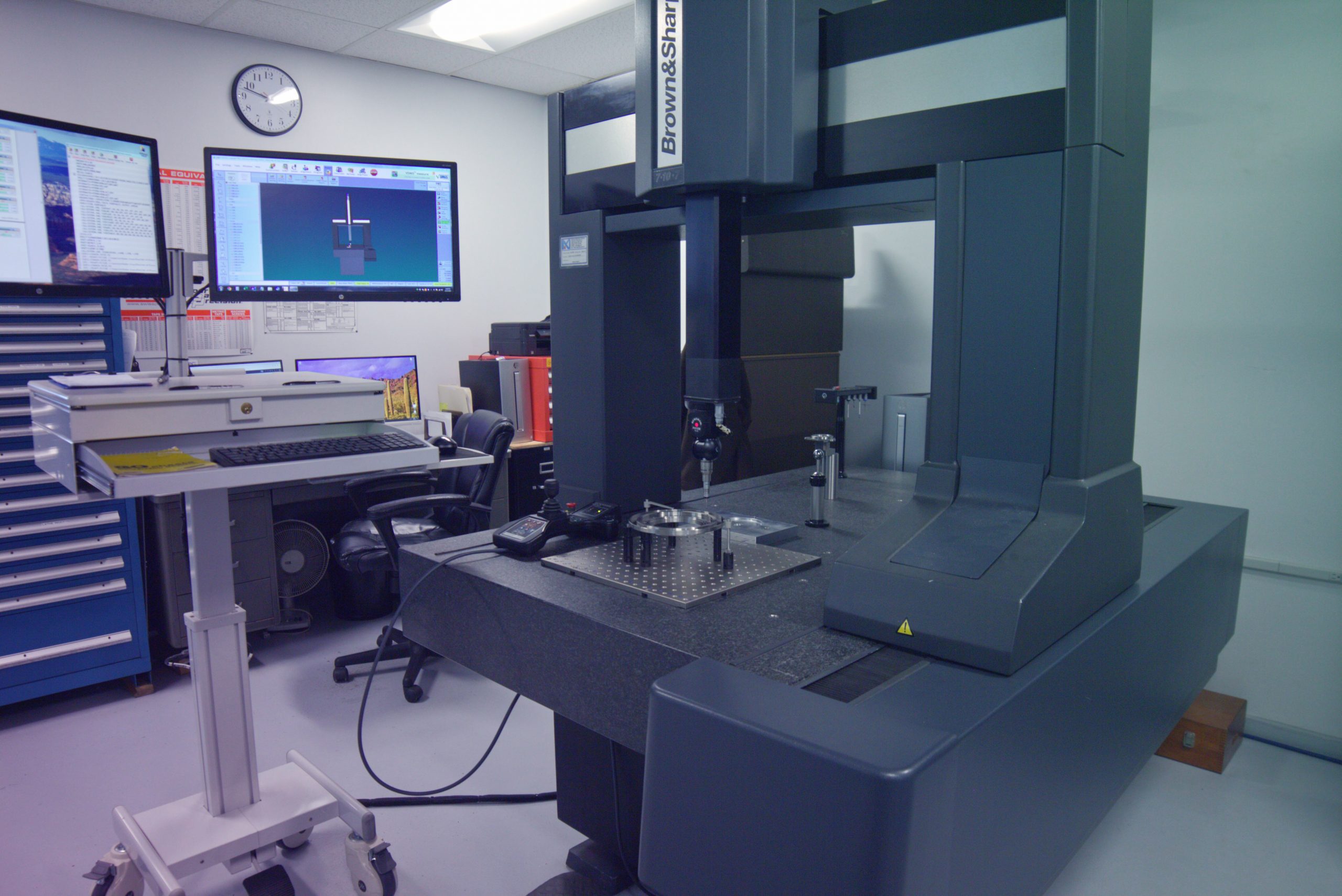

Brown and Sharp 7-10-7 CMM

The B&S 7-10-7 is the center piece of our quality system. Refurbished in 2016 with everything from new Renishaw glass scales, Control & PH10 Probe to VDMIS software right down to all new air lines. It is calibrated every 12 months to ISO standards.

Great Facilities.

Great Results.

With a tool for every job, we pride ourselves on our versatility and the exceptional quality of our work.

Want to know more? You can download our Quality Manual and a Full Facilities list for your review. Or just reach out to us if you have any questions.