Reliability Born By Experience

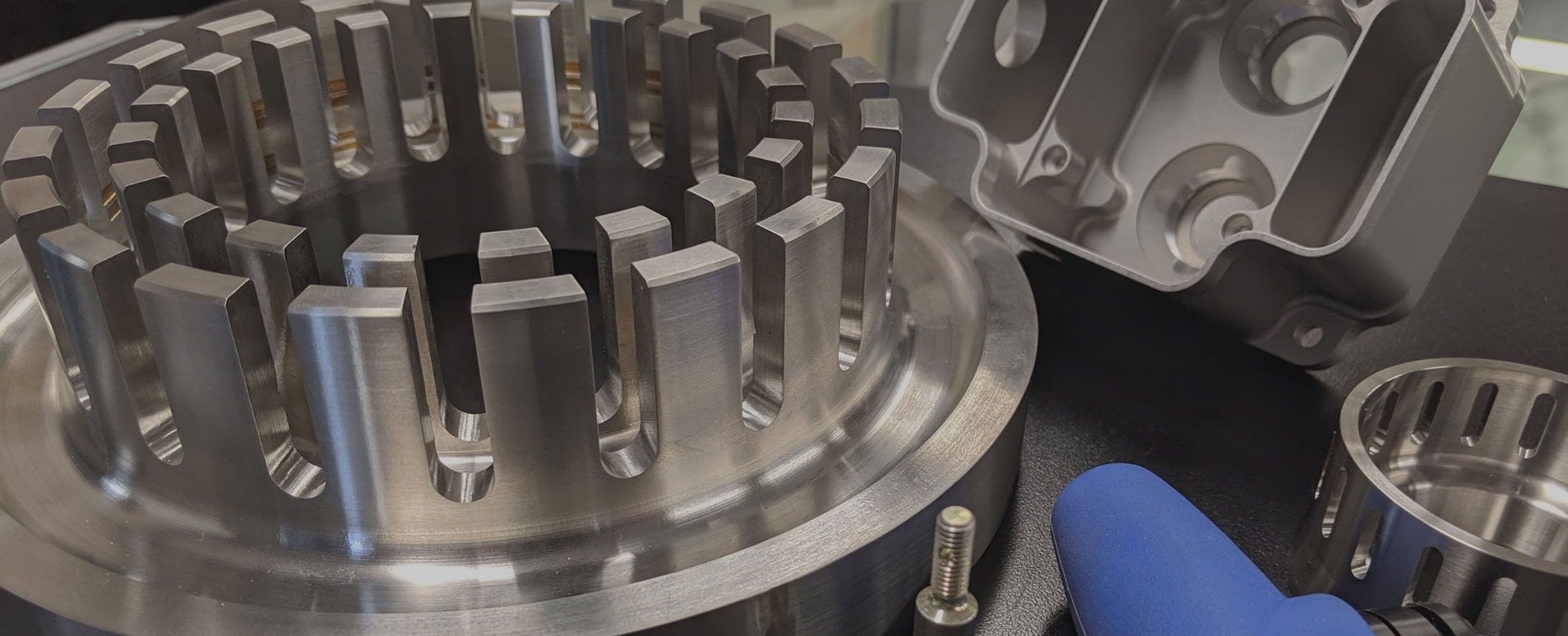

Quality

We provide the highest quality parts to our customers. Meeting even aircraft quality standards.

Detail

No matter the size of the project we’ll be sure that it comes out perfect. Just the way you want it.

Versatility

With Complete Project Support, we can take your project from initial design all the way to manufacturing.

Quality Matters

There is Industry Standard.

Then there is the RTD Standard

Here at RTD, we take the quality control process very seriously. We make sure that every part that goes out the door is perfection so you get quality parts you can rely on every time.

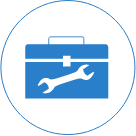

We take the guess work out of the process by using our Brown & Sharpe 7107 CMM. Completely refurbished in 2016 with new Renishaw Control, Glass Scales & PH10 Probe. It is calibrated every 12 months to ISO standards, assuring the precision and traceability required by our most demanding customers.

Interested in Quality Control for your own company?

RTD can help with your Quality Control process or if you require 3rd party inspection of your product. Contact us to discuss your needs.

Our Facilities

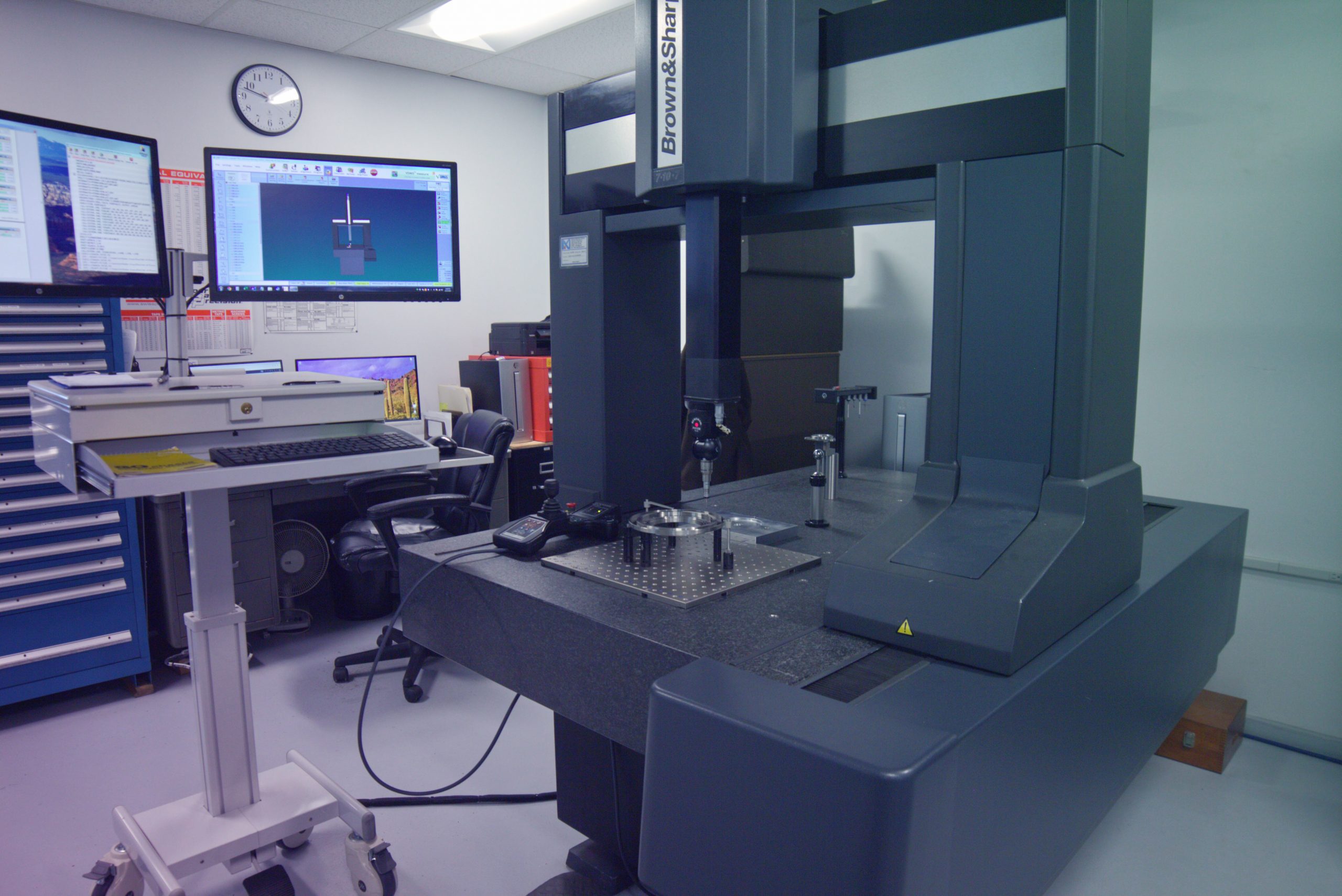

Doosan Lynx 2100LSYB

Our most recent addition. The Lynx is a Twin Spindle Live Tooling Turning Center. With the addition of an LNS QLS80 Servo Bar Feeder, Chip conveyor & Parts Accumulator, we have the ability to run lights-out 24 hours a day.

Fadal 6030 VMC

Our Largest VMC, The 6030 has a capacity of 60″ x 30″ and with a little creativity, we can usually machine parts that are even larger.

Mitsubishi FX10 Wire EDM

A small machine by todays standards, The FX10 has become an important part of our business. It’s a specialized machine that is primarily used for machining of very accurate and/or intricate shapes into ferrous metals. Whether its putting a simple keyway in a hub, or machining Titanium parts from a solid, having the capability in house allows us to better schedule and maintain quality.